The bevel angle is that angle at the edge of the razor between one side of the spine and the other. It is a major characteristic of the razor and makes a difference in how well the razor can be honed, how sharp it can be, and how robust the edge will be. It is initially determined when the razor is ground at the factory. A thinner spine for a given width of blade gives a more acute bevel angle. A thicker spine gives a more obtuse bevel angle. The bevel angle is sort of semi-permanent. It can change with inexpert honing that creates a different wear profile than was intended by the maker. If you hone with the pressure unnaturally biased to the spine, then the spine wears faster than it ought to. If the honing pressure is directed more to the edge, then width is reduced faster than the spine is reduced. Some honers apply tape to the spine of the razor, in an effort to protect it from "damage". If you are not a total idiot, you can see what this might do. And yet obviously there are times when the use of tape could correct a bevel angle that is too acute. But how do you know when it is or is not a good idea to use tape?

Quite obviously you must somehow determine what the existing bevel angle is, before making that decision.

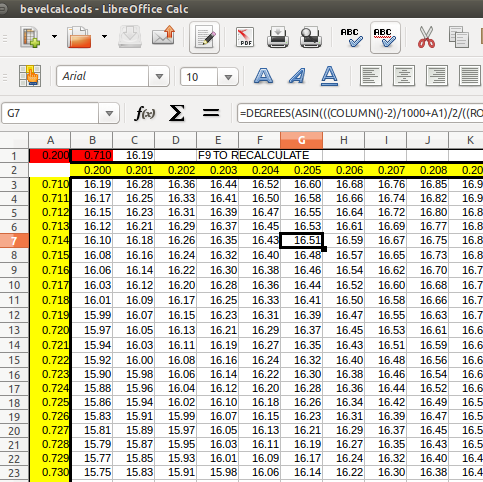

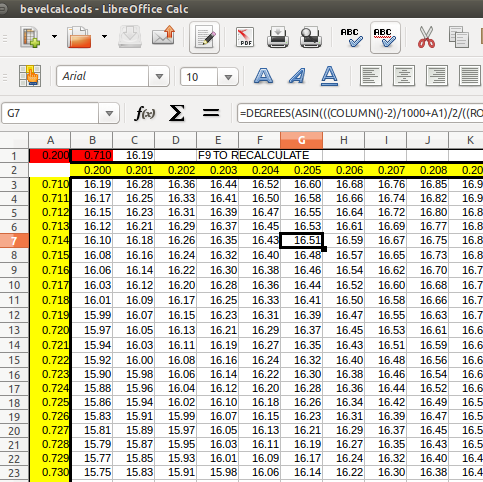

bevelcalc.ods

This is a razor bevel calculator spreadsheet in OpenOffice native

format. Try it with excel, it might work. I dont know cause I domt mess

with that Microsoft stuff. But in case it doesn't work for you WinDohs

guys, here it is in Microsoft 97 format. Aint that something... Linux

can use and even write WinBlows files but WinDOHs can't open a totally

open source file format? So much for supposed superiority of secret

source big pricetag software. Anyhow here is bevelcalc.xls

The spreadsheet doesn't do you much good if you don't know how to use

it. Well, it's not rocket science. The two red cells are user-entered

data. Enter the smallest spine thickness you expect to deal with in the

first cell, A1. The next measurement is the distance between the upper

edge of the spine bevel to the shaving edge. This is the hypotenuse of

an imaginary triangle that the spreadsheet will solve to give the bevel

angle. Enter that value in cell B1, the second red cell. Click on a cell

in the table and your spreadsheet app will calculate all possible

values for the range beginning at your entered data, and populate the

table with these values, so you can look up a hypotenuse and a spine

thickness and find the calculated bevel angle. Further, you can look at

nearby values and see what width or thickness you need to get the

desired bevel angle. And by the way, cell C1 is the bevel angle for the

entered values.

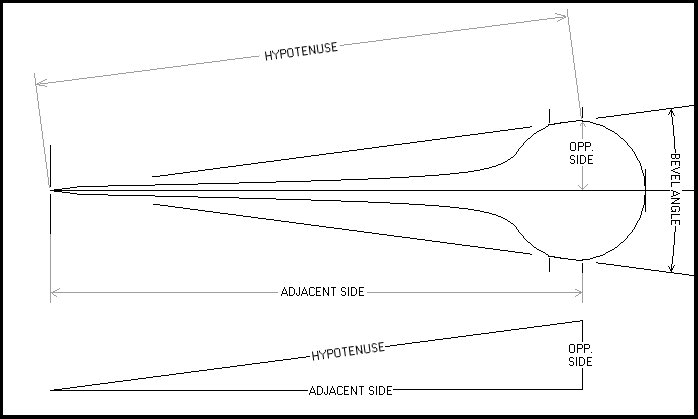

Obviously this picture is not exactly to scale. I wanted the bevel surfaces to be obvious. You can see how the bevel surface at the spine is flat and on an actual razor this flat surface can be very obvious. The "hone wear" or so called "hone damage". Look at the edge. You have a similar flat surface that many guys think is THE bevel, all the bevel, and for some reason it is okay. As the razor wears on the hone, you can see that the width of the blade is reduced, and also the thickness of the spine is reduced, as those two bevel surfaces get wider but especially at the spine. Call it damage if you like, but it is a design feature of the hollowground razor.

Notice how the Hypotenuse measurement is taken from the top edge of the spine's bevel surface, or contact area, to the shaving edge. An accurate calculation of bevel angle depends on correct measurements. You cannot use the width of the razor. Likewise, for the Opposite side of the triangle, you cannot use the total thickness of the spine. You must take half of it. The Adjacent side of the mystery triangle you cannot access directly, so we use the Hypotenuse. Because the right triangle represents half of the blade, the acute angle is doubled to give the included bevel angle, which is the figure we want.

So, if the bevel angle is too acute, i.e. the angle is too small, then honing with tape on the spine can remedy it. This happens in two ways, one immediate and one cumulative. Immediately, the tape on the spine virtually thickens the spine and makes the bevel angle larger, or more obtuse. Cumulatively, the tape would protect the spine from wear when honing, while the edge gets honed normally and the width of the razor is gradually reduced every time it is honed, but as long as tape is used when honing, the spine thickness will remain the same. It takes a lot of honing to begin making a difference. Over 20 years or so of normal use and honing, you may well see a difference.

If the bevel angle is too obtuse, obviously it could be corrected by honing with extra pressure on the spine of the razor. This, too, takes a lot of honing to begin to see a correction. If the problem is severe then you can of course grind the spine thinner on belt grinder or belt sander but this is seldom done, in practice. One problem with grinding the spine down is that in its simplest manner, it creates a large honing surface on the spine, and steel removal will be slowed considerably, so ultimately the effect will be frustratingly small.

If the howls of outrage disturb your serenity you can usually just not bother to deliberately do anything at all about the bevel angle. Many honers, even professionals, hone with tape for no particular reason at all, except for aesthetics. They will often protest that unskilled honers for some reason cause the spine to be thinned unnaturally and so honing with tape is doing the razor a favor from a mathematical standpoint. Go ahead and drink the koolaid if you like, and buy into that baseless and flawed logic. You won't be hurting the razor very much. The exception to this is when you are removing a LoT of steel, as when doing major edge repair. In that event, it is most unwise to hone without tape unless you are certain that the spine is too thin as it is, and this is a good time to reduce the width of the razor while maintaining the spine thickness. Paradoxically, this is when both the always tape crowd and the uncommitted fence sitters will insist that the razor must be taped to "save" the spine from "damage". Don't let me stop you. Not my razor. But at least now you know the error of those ways. Tape is a valuable tool when used for good, when its use is logically and mathematically indicated. It is foolishness when done for no particular reason, or out of misguided belief that it is necessary without even calculating the bevel angle. And now you know how to do it, and you no longer have to pretend that it is not necessary. So check that bevel angle if there is any doubt. Use tape if the bevel angle is too acute. Do not use it if it is exactly where it ought to be. Consider remedial spine thinning if it is much too obtuse.

Honing a wedge is a whole nother critter. Read the chapter on wedge honing. This page refers to hollowground razors.

Some razors are treated more as jewelry or art than as tools. That's okay, as long as you think about what you are doing and about what you want out of the razor. If it is to be a showpiece, by all means, hone it with tape on the spine to maintain its virginal appearance. Or better yet, do not hone it at all. A razor, no matter how fancy, that is to be part of your regular rotation, is a tool. Treat it as a tool. If you have a hammer, even a very fancy one, that you will be using to hammer on stuff, do you protect the head against "damage" such as tyny dents or scratches? Do you protect a saw's teeth from wear when you sharpen them? How about your chisels... do you tape them when you use or sharpen them? They are tools. So is your razor. Honest wear from normal use is not a shame on the tool's owner or a disrespect to the tool.

One of the stupidest arguments in favor of tape is really not an argument in its favor, but merely a futile effort at disarming arguments against it. This is the smugly delivered statement, obviously true but irrelevant, that it takes many years of honing with tape to change the bevel angle. Well first of all the converse is also true. It takes many years of honing WITHOUT tape to have an effect, too, except perhaps cosmetically. These same persons will declare that "hone wear" on the spine is "ugly" or "disfiguring". Yeah. About like a scratch on the blade of your pocketknife, or a dent or two on the head of your favorite hammer. Get real. This is a tool. Use it and maintain it with an eye on keeping it available for efficient use, not with an irrational goal of making it look like the razor has never been used for its intended task. But back to the "many years" thing... just how many years is the razor capable of being regularly used, anyway? Why deliberately damage it just because the damage takes a decade or more to become detectable? Don't be so shortsighted. The vintage razors you own now are still around because either they were lightly used, or they were properly maintained, or both. Yours could be usable 100 years from now. So what if you are dead? Somebody will appreciate them and appreciate the care you took to hone them correctly while you owned them.

In a supreme manic effort to invalidate the logic against honing with tape, it is said that the newbie will usually put too much honing pressure on the spine. And this ruins the razor. So, newbies should always hone with tape. Okay, then what about those who put too much pressure on the edge? Or just the right amount of pressure on the edge? Same amount, more or less, of bevel angle change. Tape saves some razors from "damage", real or imagined, but causes the same effective change to others.

As this document is aimed at the newbie, I think it can be assumed that the razor you hone is your own, and not someone else's. So, your razor. Tape automatically if you want. Never tape at all if you want. Tape when the math tells you that you should tape, if you want. But don't delude yourself. By "saving" the spine, you probably aren't doing your razor any favors unless the spine is already too thin. If you are prone to applying too much pressure to the spine, then well, don't DO that. LOL!